Converting Your Digital Ideas Into Reality

3Dmatic provides an online 3D printing service for all people with a creative vision

Australia’s leading 3D Printing and Rapid Prototyping Service

3Dmatic is an advanced 3D printing services provider in Australia. Send us your files, and we will create 3D prototypes or even usable products using our 3D printing or additive manufacturing machines. We use high-quality imported machines and plastic. Bring your designs to life and get a real-life feel for products, buildings, handheld devices, and or anything else you dream of. These machines can create usable objects, not just working prototypes!

Where does 3D Printing come in handy for you?

Cutting-edge 3D printing technology can be useful in various ways. It has applications in almost every industry, as it provides an alternative to traditional manufacturing methods.

RAPID PROTOTYPING

Seeing is believing. Use our advanced 3D printers to have a look at your creations before coming to life.

UNLEASH CREATIVITY

Want to give shape to your ideas? Want to bring your dream design to life? Rely on 3D printing technology.

PERSONALISED GIFTING

Use your creativity to personalise gifts for your loved ones for special occasions. Give a shape and add life to your feelings.

MINIATURE MODELS

Create a miniature replica for your creation or your house or car to cherish for years to come.

Applications of 3D Printing

3D Printing Technology has expanded into various industries

AEROSPACE

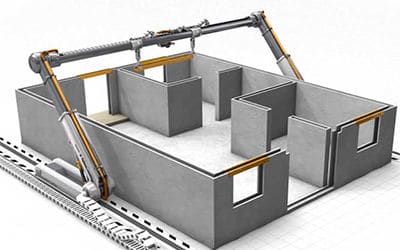

ARCHITECTURE

AUTOMOTIVE

CONSUMER ELECTRONICS

COMMERCIAL GOODS

DENTAL INDUSTRY

EDUCATION INDUSTRY

COMMERCIAL GOODS

MILITARY INDUSTRY

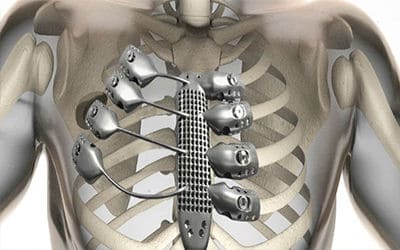

MEDICAL INDUSTRY

MOLD INDUSTRY

How Can I Submit My Design?

Provide the “.STL” file of your design. You can do the same by uploading it to the enquiry box at the bottom of this page or dropping an email to info@3dmatic.com.au. We will check/repair the design and let you know the estimated price. We will also require information on the design’s preferred material /colour and required output size.

Once we get the details, we will call you if we need any more information and then send you the detailed quote, including shipping and applicable taxes.

What if I do not have a 3D Model File?

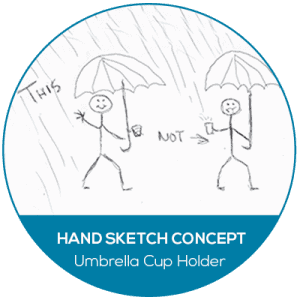

If you have a novel idea, we will help you design it, evolve your concept, and print it using our 3D printers. Got just a 2D design of your concept? Do not worry! We can help you give shape with our in-house designers.

STEP 1

CONCEPT DESIGN

Send us your 2D Image File or Draft of your concept.

STEP 2

3D MODEL

We will design and produce the 3D Model for your concept.

STEP 3

3D PRINTED PRODUCT

3D Printed Product for your concept design is ready to be delivered!

What materials are used?

Currently, we support the thermoplastic materials PLA and ABS, which will cater to the majority of the requirements. More materials will be added in the future.

Which locations are serviced by 3Dmatic?

We are just an email away from Australia-wide 3D printing/ rapid prototyping needs.

Any information on the delivery timelines?

Receiving and finalizing the STL file is the key. Once we have a final STL file ready, we can ship the printed 3D model within 3-5 business working days.